CNC Soft and Hard Jaws – Custom Steel Jaws

Description & Features

We offer CNC soft jaws machined from steel or aluminum alloys (e.g., En24, En36) for custom clamping solutions. Soft jaws are easy to contour‑machined for unique workpiece profiles and reduce workpiece deformation—ideal for thin-walled or delicate components.

Our hard jaws are precision ground from hardened tool steel (D2, Caldie/Dievar), heat-treated for durability and rigidity in heavy-duty CNC machining applications. They deliver consistent concentricity and withstand higher clamping forces compared to soft jaws.

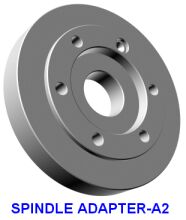

Spindle Adapters – High‑Precision Chuck Adaptors

Description & Features

Precision spindle adapters with A2 and CamLock taper options, engineered to maintain concentricity within ≤ 0.005 mm runout between taper bore and chuck mounting OD. Ideal for high-speed CNC turning and milling.

Drilled and threaded for standard spindle interfaces. Low-runout tolerance (≤ 0.002″) ensures stable chuck performance, extending tool life and improving surface finish for automotive, aerospace, and precision engineering applications.

Bearing Housing – Precision Ball-Screw End Support

Description & Features

High-precision bearing housings engineered to locate CNC ball-screw ends with bore axis parallelism within 0.005 mm to the mounting face. Designed to minimize radial and angular load, improving machine accuracy.

Utilizes ABEC‑5/P4A double‑row angular contact bearings in preload assembly, ideal for high-speed, high-load CNC applications. Proper housing preload reduces vibration, extends service life, and supports repeatable motion accuracy.

Inspection Mandrels – Spindle Alignment Gauges

Description & Features

Inspection mandrels for ISO and Morse taper spindles, hardened and precision ground to within 0.003–0.005 µm concentricity and perpendicularity. Used for spindle axis alignment, centre straightness, and perpendicularity checks.

Equipped with ground reference flats and tapped ends or draw-nut access for easy extraction. Essential for precision calibration and maintenance in CNC turning centres and milling machines.

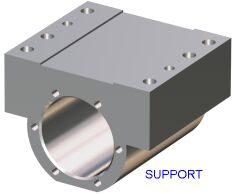

Other Spares – CNC Lathe Spindles & Supports

Description & Features

Comprehensive range of CNC spare parts including boss components and flanges machined in high-grade steel with ISO tolerance fits.

Headstock and tailstock spindles (hydraulic quills included) are balanced for minimal runout and built to OEM tolerance. Right-angled mandrels and robust supports processed through heat-treatment and finish-grinding ensure structural precision.