Nomenclature

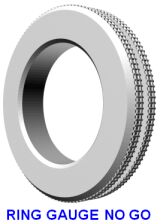

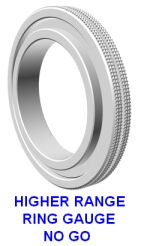

- "Go and No-Go" Gauge (for Checking shafts)

- Plain Ring Gauge

Selection & Ordering

To select the right sizes of Smitra Ring Gauges consider these points:

- Specify the diameters of the shafts to be measured and their manufacturing tolerances. Once the tolerances are specified the Ring Gauge designs are automatically selected as per IS, BS, DIN standards.

Description & Features

- Made out of Superior Quality High Chrome Alloy Steel.

- Quality Heat Treated and hardened to 58-60 HRC, to provide a High Degree of Wear Resistance.

- Finely Lapped to get Maximum Seating & Surface Finish.

- Sub-zero treated to Take Care of distortion throughout a Long & Stable Life Span of Gauges.

Common Uses

- The Ring gauges are used to measure shafts and other cylindrical male parts which are to be manufactured within a given tolerance.

- The Ring Gauges are mainly used in areas of mass production where the shafts (of components) are machined for interchangeable fit with female parts.

Scope of Supply

The Smitra Ring Gauges are available as separate "Go" and "No-Go" rings. For easy identification, all "no-go" rings are provided with a groove marking on the outside diameter.

Ordering Example

- Smitra Ring Gauge : 35H7 + 0.2 / Go

- Smitra Ring Gauge : 15 + 0.35 / No-Go

Interested in the Ring Gauge?

Get a quote or ask us about the Ring Gauge.

Contact Us About This Product